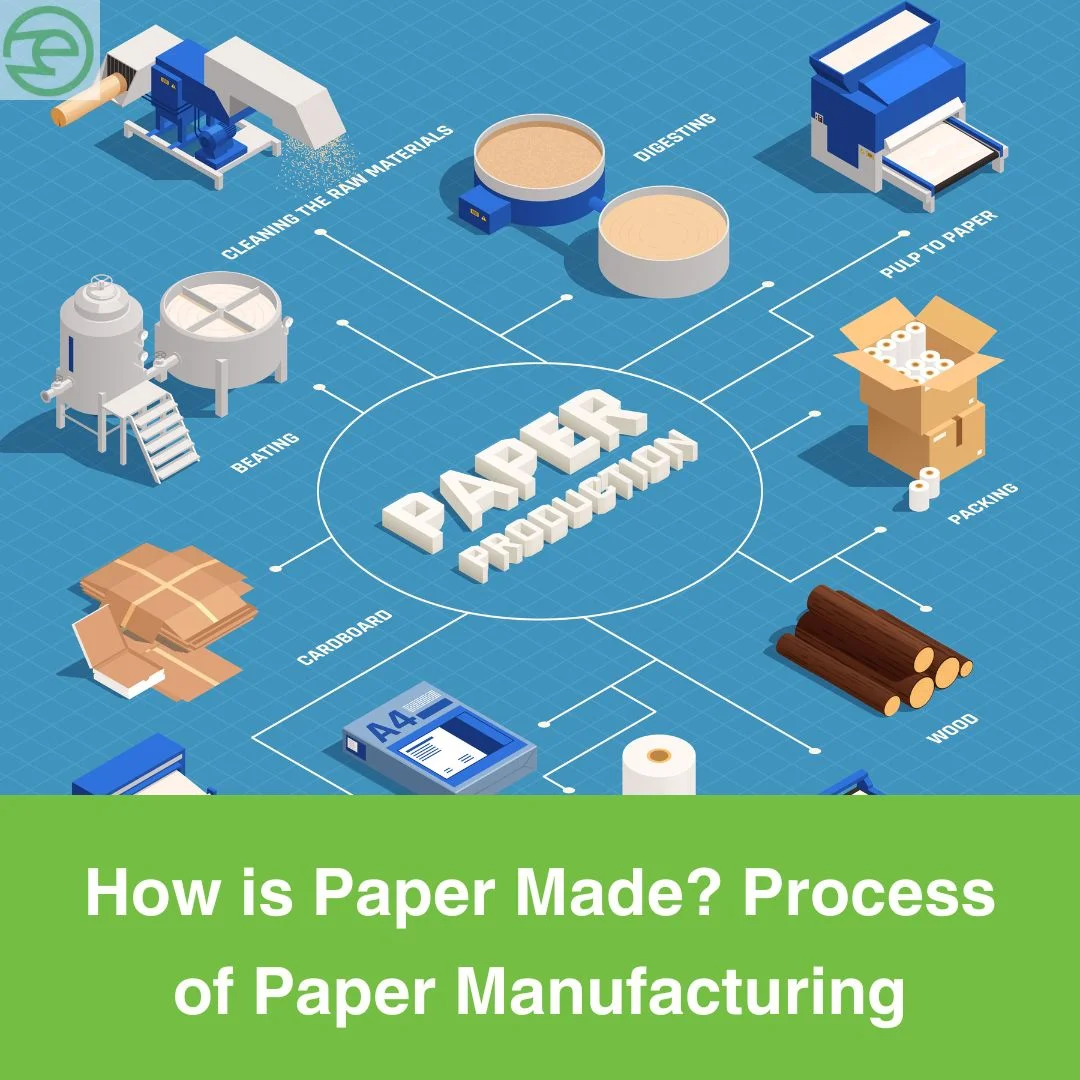

How is Paper Made? Process of Paper Manufacturing

Introduction: The Alchemy of Paper

In the quiet corners of every office and the bustling realms of packaging, lies an ancient craft that often escapes the spotlight – the alchemy of papermaking. This isn't just about trees becoming pages; it's a bewitching journey from pulp to reel. But this isn't a tale of mere dilution; it's a symphony of watery stock falling onto the wire, where suction boxes and foils perform a ballet to weave fibers into a tight mat.

It's the magic of nip rollers squeezing water out, crafting density, and a sheet that emerges not just dry but 80-85% dry, steamed to perfection. And as it passes through smooth rollers, gaining a glossy face, it's the finishing touch to a spellbinding transformation. But, before this grand reveal, automated inspectors, like mystical guardians, ensure perfection in every inch of the paper oracle. The journey begins; the alchemy unfolds – welcome to the enchanting world of papermaking.

Step 1: Brewing the Pulp Potion

Step 2: Thinning the Fibres

Step 3: Weaving the Spellbinding Mats

Step 4: Squeezing the Magic Out - Crafting Density and Fiber Fusion

Step 5: Drying - A Steamy Transformation

Step 6: Finishing Flourish

Step 7: Quality Control - The Watchful Eye

Step 8: The Grand Unveiling - Paper Winding

Step 9: The Paper Oracle - Testing Wisdom

Step 1: Brewing the Pulp Potion

In the mystical realms of paper creation, the alchemists at work are not conjuring spells but brewing a potion called pulp. The recycled paper meets a watery fate, stirred in the grand stainless steel pulper - a cauldron of paper potential.

Whisking through screens, impurities vanish - a purification dance ensuring only the finest paper emerges, a testament to the eco-friendly magic embedded in the process.

This pulp and paper dance isn't a mere choreography; it's a green symphony, where the by-product of paper-making becomes a protagonist, delivering high-quality results without bowing to environmental woes.

The pulper, the silent hero, transforms waste into wonder, setting the stage for an eco-conscious saga in the enchanted world of paper manufacturing.

Step 2: Thinning the Fibres

In the papermaking cauldron, a symphony begins. Recycled paper meets water, swirling in the pulper, a stainless steel wizard's vat. Screens sift through the potion, purging impurities. The alchemy? A delicate dance of 1% fiber and 99% water. A transformative brew, as environmental guardians ensure paper gold without harming the realm.

This isn't mere dilution; it's the crafting of a potion, a concoction destined for thin, uniform paper. The alchemists extract water, leaving behind the essence, preparing for the next enchanting steps.

Step 3: Weaving the Spellbinding Mats

Behold the sacred rite of Step 3 – where the elemental forces of water and fiber converge in a dance orchestrated by the mystical headbox. The watery mixtures falls gracefully onto the wire, guided by foils and suction boxes, weaving a chunk of pulp, transforming chaos into a soft mat of promise. In a mere blink, 30-40 meters traverse, and the wet sheen surrenders to the process. Here, in the process of the paper machine, fibers unite in a tight mat, birthing the parchment's core – the elusive paper mats.

Step 4: Squeezing the Magic Out - Crafting Density and Fiber Fusion

In the intricate stage of paper creation, the press section takes center stage, orchestrating a symphony of water expulsion and fiber fusion. Nip rollers, squeeze the liquid essence from the pulp mat. This not only wrings out water but crafts a dense, smooth sheet - the canvas for the paper masterpiece.

With each revolution, the fibers intertwine, a silent dance of alchemical proportions, transforming chaos into cohesion. The pressure applied is the secret sauce, turning the wet concoction into a paper phoenix rising, ready to embark on its next magical metamorphosis.

Step 5: Drying - A Steamy Transformation

In the chambers of our paper creation, the soggy journey takes a steamy turn. Encased within heated cylinders, the paper web embarks on a 400-meter odyssey, shedding wetness and emerging from the mist. At 130ºC, the transformation begins, turning the paper into a vessel of 80 to 85% dry wisdom. Meanwhile, a meticulous dance unfolds – wet sizing solutions delicately applied, starch layers bonding fibers like ancient scrolls being interwoven. The symphony concludes as the paper web journeys through a legion of heated cylinders, ready for its final enchantment.

Step 6: Finishing Flourish

In the final act, smooth rollers take center stage. They press against the paper, shaping a surface that’s not just smooth but almost magically glossy. It's a dance between hardness and softness, a tactile poetry etched onto each sheet. The machinery orchestrates a delicate balance, ensuring the paper emerges not just finished but transformed. A finishing touch that goes beyond the eye, inviting fingertips to glide over a surface crafted with precision. It’s not just paper; it’s the embodiment of meticulous perfection.

Step 7: Quality Control - The Watchful Eye

During this inspection stage, automated inspectors do their invisible magic. They identify flaws—the elusive enemies of pristine paper—with painstaking precision. They protect the integrity of our paper production with a dance of codes and algorithms, making sure every page is a tribute to excellence. It's a ballet of data, where flaws meet their silent end and the alchemy of excellence triumphs—not visible but felt all the same.

Step 8: The Grand Unveiling - Paper Winding

Bearing witness to the creation, the paper exits the machine, a 500-meter opus of cellulose. The jumbo reel, a seven-meter titan, lifted by the crane in a silent symphony. It unwinds like the unveiling of an ancient scroll, revealing its textured secrets. With precision, it's cut into smaller scrolls, each carrying the whispers of its journey. Labels mark the identity of the newborn paper progeny, ready to embark on diverse adventures beyond the realm of the manufacturing wizardry.

Step 9: The Paper Oracle - Testing Wisdom

In the sections of Quality Control Laboratories, where precision reigns supreme, paper undergoes its final scrutiny. Automated inspectors, scan for imperfections again. Regular samples are taken, affirming the sacred commitment to deliver only the highest quality paper. It's here that the mystique of manufacturing culminates, a testament to the meticulous wisdom applied in the papermaking alchemy.

In Conclusion

The quiet creativity is shown in the symphony of paper manufacture, from the modest pulp to the great reel. Every action is a brushstroke on the often-overlooked canvas of a skill. A tale of painstaking sorcery unfolds, from the pulper's alchemy to the accuracy of quality control.

Leading the way with a unique line is Edicon Paper Products, a lighthouse in this magical world. Every sheet they create tells a story, from the sturdy Iconic Ocean, Iconic Era to the exquisite Iconic Crema, Iconic Velvet.

Thanks to the artists at Edicon Paper Products, readers leave this story with a greater respect for the invisible as well as information.