Basics of Duplex Board Paper Manufacturing

The World of Duplex Boards

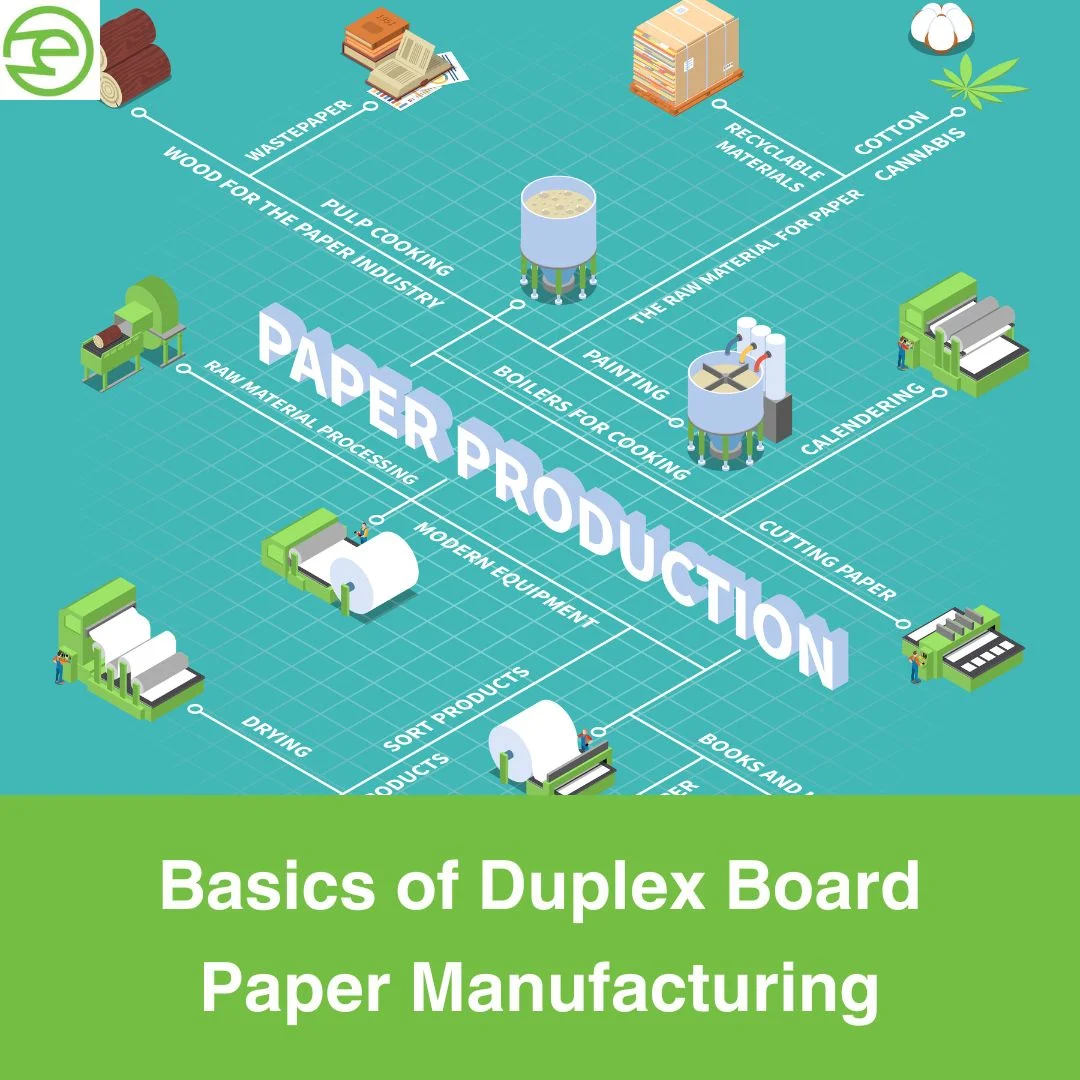

Duplex board paper is a truly pivotal element in the big printing and packaging industry. It is very versatile and reliable, which is what industries cannot do without. However, you must wonder how sturdy this impressive paper superhero is.

Come on a journey with us to get to know about the complexities of duplex board paper production. Learning elementary things that are behind every sheet of paper will lead to an appreciation of all the craftsmanship that goes into every single one. Edicon Paper Product welcomes you to explore this mysterious area fully, where innovations are followed by tradition to manufacture superlative duplex board papers.

Let's navigate the intricacies of this little wonder, without which the present-day packaging and printing would be unimaginable.

Raw Materials

The process of duplex paperboard manufacturing involves a number of materials of choice carefully selected in order to produce a harmonious blend. Materials, which include wood pulp and re-pulped paper, act as the foundation of high-quality duplex board production. The careful selection of raw materials is of the essence to achieving the right characteristics in the end product which is a direct outcome of the quality of raw materials.

![]()

By an admixture of diverse elements that focus on quality and uniformity manufacturers such as Edicon Paper Product achieve their sales of duplex board. Every ingredient is in itself a significant one, making its contribution to the unique mixture.

It’s a melodic alliance of parts that makes the quality and performance attainable, rendering the idea of manufacturing.

The Paper-making Process unfolds as follows:

1. Pulping process

2. Papermaking process

3. Coating Process

4. Drying and Finishing Process

Pulping Process

The pulping process, which is at the core of duplex board production, starts the conversion of initial components into pulp and thereby determines the final product’s quality.

![]()

• Breaking Down Materials: The first step in the manufacturing process is the mechanical or chemical breaking down of raw materials into chips or recycled paper by various instruments to prepare the materials for the next steps.

• Fiber Separation: Different techniques such as grinding and chemical digestion are used to break the fibers and together they form a tissue mixture.

• Refining for Quality: Next, the pulp is mechanically defibrated ensuring adequate fiber length and proper consistency, both of which are essential for the duplex board's strength and surface.

• Optimizing Properties: The pulping process doesn't just rip up the material; rather, it changes it into a versatile fabric that can be formed into different products ranging from the heavy duty duplex board in packaging to fine printing materials.

Papermaking Process

In the center of duplex board production stands the complex art of papermaking, the process that takes the primary materials of nature to make the diverse fabric we daily use in packaging and printing.

![]()

• Blending and Beating: The mixture goes through a scrupulous mixing process after which it enters the beater, where it is subjected to pulping and refining to attain the preferred level of consistency.

• Forming: Pulpy mass is then spread onto a wire mesh and water drains off, keeping just a delicate lace of fibers which are the basis of the duplex board.

• Pressing: Excess water is squeezed out, compacting the fibers and providing increased strength.

• Drying: The waiter paper passes from one hot roller to another through the high temperature and is still kept damp for the next operation.

• Finishing: The surface treatment may achieve additional procedures related to the degree of smoothness and printability, with the final result to be of the highest class.

Coating Process

Important in coating process is the next step called “paper coatings” that in fact make the surface properties of duplex boards better and stronger. This involves the selection of pigments, binders, and additives as well as formulating them in a manner that maximizes printability and longevity.

Edicon applies cutting-edge coating methods that promote uniform coverage and stability to the products at all times. Through this procedure, the cardboard becomes smooth and bright. It also enhances the receptivity of ink, and it is therefore ultimately suitable for accurate and sharp printing.

The availability of modern coating technology has been of paramount importance for Edicon in establishing itself as a leader in duplex board solutions that cater to special customized print and packaging needs.

Drying and Finishing

Drying Methods: Usually after papermaking, duplex boarding proceeds to drying which is done by hot air drying, or infrared drying. This essential stage brings about the eviction of moisture from the board, which in turn adds to the strength and stability of the product.

![]()

Finishing Processes: The finished products are taken through different processes, including calendaring and surface finishing. The process of calendaring includes rollers that modify the candidate surface’s finish. Surface treatments, such as coating and embossing, among other techniques, induce additional characteristics specific to different applications.

Quality Control: Strict and fair quality control standards must be maintained during the drying and finishing to maintain product consistency and to correspond to industry standards. The measures taken include moisture monitoring, surface roughness, and performance tests to support the production of the final product that is up to the expectations of the customer.

Conclusion

In concluding this informative tour through the extensive procedures of duplex board paper manufacturing you may already be stunned by the complexity of the production of this indispensable material. From the very first instance of pulping to the tight end of lamination and finishing, every one of the individual processes has a key role in the quality of and the specific features of the final product.

Understanding these foundations is critical for both professionals and fans, as it offers a greater appreciation for the artistry that goes into each sheet of duplex board. As readers explore this business, Edicon Paper Product stands out as a shining example of excellence, providing a wide choice of high-quality duplex board solutions.

Whether it's the adaptable Iconic Ocean, the dependable Iconic Era, or the inventive Iconic Crema, Edicon's dedication to quality is evident in every model. Businesses can rely on Edicon, their trusted manufacturer and supplier, to suit their packaging and printing needs with top-tier duplex board solutions.