Duplex Board Thickness Chart: Microns vs GSM Explained

Picking the right paper for your print job can feel like a puzzle. You see terms like GSM and microns thrown around, and it's easy to get confused. What's the real difference between paper weight and thickness, especially when you're looking at a duplex paper board? This guide breaks down Duplex Board Thickness, Microns vs GSM, and how these measurements affect your final print, whether it's for business cards or packaging.

Key Takeaways

-

GSM measures paper weight per square meter, while microns measure its physical thickness.

-

While often related, GSM doesn't always directly dictate thickness; fiber type and manufacturing affect the final micron count.

-

Choosing the correct duplex paper weight and thickness impacts durability, print quality, and the overall feel of your project.

-

Thicker duplex paper boards (higher GSM and microns) are generally better for items needing durability like business cards and packaging.

-

Understanding both GSM and micron measurements helps you select the ideal duplex paper board for specific applications.

Understanding Paper Weight: GSM Explained

What GSM Signifies in Paper

Ever picked up a piece of paper and just knew it was different? Maybe it felt flimsy, or perhaps it had a satisfying heft. That feeling often comes down to something called GSM. GSM stands for grams per square meter. It's basically a way to measure how much a square meter of paper weighs. Think of it like this: if you could cut out a perfect one-meter by one-meter square from a sheet of paper, GSM tells you how many grams that square would weigh.

So, a higher GSM number means the paper is heavier. This usually translates to the paper being thicker and more robust. For example, standard printer paper might be around 80 GSM it’s light and flexible. But if you’re looking at cardstock for business cards or a sturdy brochure, you’ll likely see numbers like 250 GSM or even 400 GSM. That heavier weight gives it a more premium feel and makes it stand up better to handling.

It's important to remember that GSM is about weight, not directly thickness. Sometimes, papers with the same GSM can feel different in thickness. This can happen because of how the paper is made, its texture, or even how much air is trapped within its fibers. For instance, a textured paper might feel bulkier than a smooth, compact paper, even if they both weigh the same per square meter.

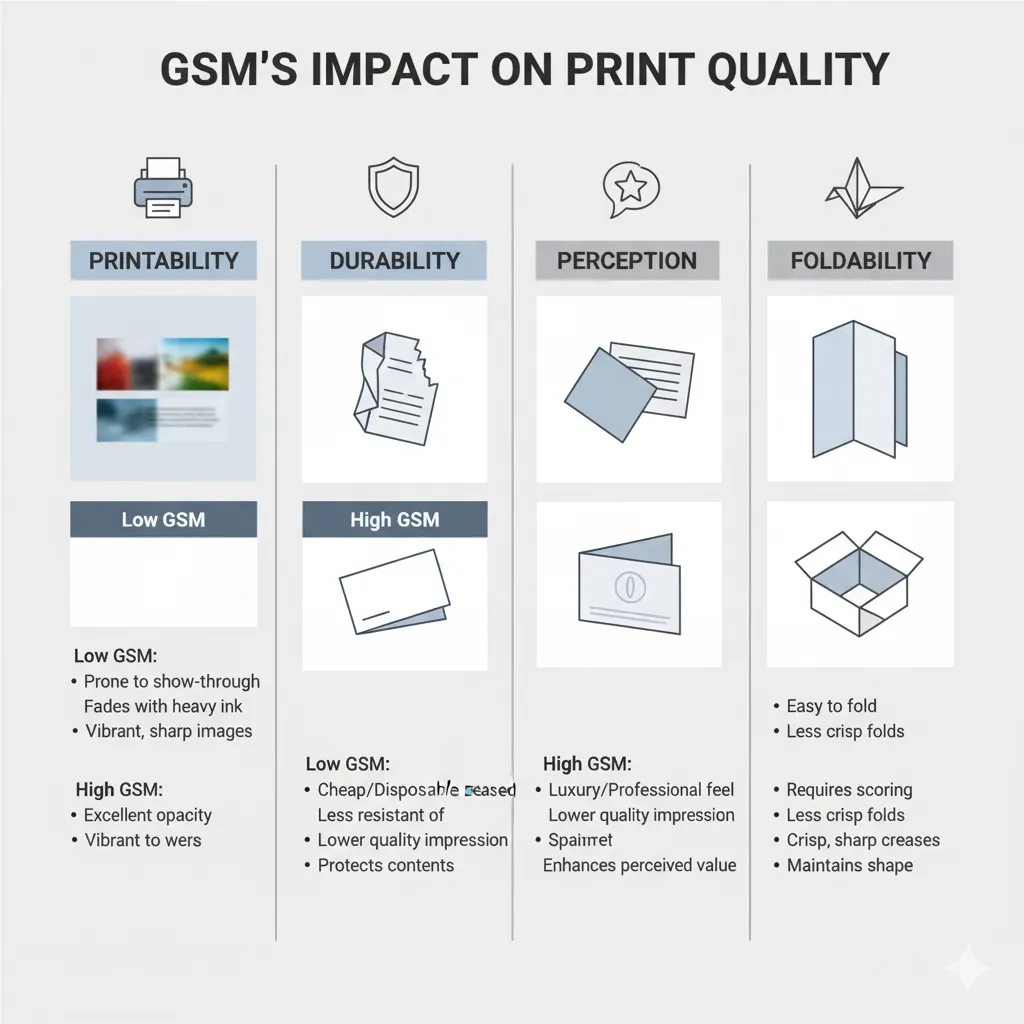

GSM's Impact on Print Quality

The GSM you choose for your project really does make a difference in how your printed materials look and feel. It’s not just about weight; it affects the overall impression.

-

Durability: Heavier GSM papers (like 300 GSM and up) are generally more durable. They hold up better to folding, bending, and general handling, which is great for things like business cards or packaging that get touched a lot.

-

Perception: A higher GSM often signals quality. Think about wedding invitations or premium flyers they usually use thicker paper to convey a sense of luxury and importance.

-

Printability: While most modern printers can handle a range of GSMs, very heavy cardstock might require a printer specifically designed for it. Also, the paper's finish (like gloss or matte) can interact with the GSM to affect how ink sits on the surface.

-

Foldability: If your project needs to be folded, like a brochure or a greeting card, the GSM plays a role. Papers that are too thick might crack when folded, even if they feel substantial. Lighter GSMs (like 150-200 GSM) are often better for clean folds.

Choosing the right GSM is a balancing act. You want your print to feel substantial and look good, but it also needs to be practical for its intended use. A flyer that’s too stiff might be awkward to hand out, while a business card that’s too flimsy might not make the best first impression.

Choosing the Right GSM for Your Project

So, how do you pick the perfect GSM? It really comes down to what you’re making and what you want it to achieve.

Here’s a quick guide:

-

Letterheads & Basic Documents: Around 90-120 GSM is usually fine. It’s sturdy enough for everyday use but not overly heavy.

-

Flyers & Posters: 150-200 GSM often hits the sweet spot. It’s heavier than regular paper, giving it a bit more presence, but still easy to handle and distribute.

-

Brochures & Folded Cards: 200-250 GSM works well. It’s thick enough to feel good when folded but not so thick that it becomes difficult to crease cleanly.

-

Business Cards & Premium Stationery: This is where you’ll see higher GSMs, typically 300 GSM and above, sometimes even up to 700 GSM for very thick cards. This weight communicates quality and durability.

-

Packaging: Depends heavily on the product, but often requires thicker, more rigid boards, which will have even higher GSM equivalents.

Consider how the item will be used. Will it be mailed? Handed out? Kept on a desk? The answer will guide you toward the GSM that best fits the job.

Decoding Duplex Board Thickness: Microns vs GSM

![]()

So, we've talked about GSM, which is basically how much a square meter of paper weighs. But what about thickness? That's where microns come in. It's easy to think that if two papers have the same GSM, they'll be the same thickness, right? Well, not always.

Microns: The Measurement of Thickness

Microns, or micrometers (µm), are the actual measurement of how thick the paper board is. Think of it like this: 1 micron is just one-thousandth of a millimeter. So, a board that's 300 microns thick is 0.3 millimeters. This measurement is pretty straightforward and tells you the physical dimension of the board.

GSM: The Measurement of Weight

GSM, or grams per square meter, tells you how heavy a sheet of paper is. It's a good indicator of the paper's substance, but it doesn't directly tell you its thickness. Why the difference? Well, how a paper is made matters. Some papers are pressed really tight during manufacturing, making them denser and thinner, even if they weigh the same as a looser, airier paper.

| Aspect | GSM (Weight) | Microns (Thickness) |

|---|---|---|

| Unit | g/m² | µm (micrometres) |

| Focus | Mass per area | Physical thickness |

| Impact | Print quality, shipping cost | Stiffness, feel, machine settings |

| Who Uses | Printers, buyers | Packaging engineers, machine operators |

Duplex Board Thickness Chart (Microns vs GSM)

Below is an approximate conversion chart based on typical coated duplex board densities.

(Values can vary ±10% by manufacturer and moisture content.)

| GSM (g/m²) | Thickness (Microns) | Typical Application |

|---|---|---|

| 200 GSM | 230–250 µm | Small cartons, inner sleeves |

| 230 GSM | 280–300 µm | Food sleeves, lightweight boxes |

| 250 GSM | 310–330 µm | FMCG packs, stationery |

| 280 GSM | 340–360 µm | Cosmetic & pharma cartons |

| 300 GSM | 370–390 µm | Mid-range food packaging |

| 350 GSM | 440–460 µm | Rigid boxes, auto-lock cartons |

| 400 GSM | 500–550 µm | Premium beverage packaging |

| 450 GSM | 580–600 µm | Heavy-duty cartons |

| 500 GSM | 630–650 µm | Industrial packaging |

Understanding both measurements is key. If you need your printed material to fit a specific space, like a box or an envelope, the micron measurement is probably more important. If you're going for a certain feel or durability, GSM might be your primary guide. For lightweight products such as FMCG, electrical, and light electronics, duplex packaging board with a thickness of 300-400 microns or a weight of 250-350 GSM is recommended.

Factors Influencing Duplex Paper Thickness

![]()

So, you're looking at duplex board and wondering why two boards with the same GSM might feel or look different in thickness? It's not magic, it's just how paper is made. Several things play a role in how thick that board actually ends up being, even if the weight (GSM) is the same.

Fibre Composition and Density

The type of fibres used and how tightly they're packed together really matters. Think of it like building with different materials. Some fibres are naturally fluffier, creating more air pockets within the paper structure. This can make the board feel thicker and bulkier, even if it weighs the same as a more compact board made from denser fibres. Recycled papers, for instance, often have a bit more character and airiness due to the nature of their fibres and processing, which can lead to a slightly higher bulk.

Manufacturing Processes and Compression

How the paper is actually made has a big impact too. During production, the paper pulp goes through rollers. The amount of pressure applied during this process, known as compression, directly affects the final thickness. More compression means a denser, flatter board, which will likely be thinner for a given weight. Less compression leaves more air in the fibres, resulting in a thicker, bulkier feel. It’s a balancing act manufacturers perform to achieve specific paper characteristics.

Surface Treatments and Coatings

Sometimes, the surface of the duplex board grey back gets treated or coated. These coatings, whether they're for gloss, a matte finish, or even a protective layer, can add a small amount of thickness. While usually not a huge difference, it's another factor that contributes to the overall caliper (thickness measurement) of the board. A heavily coated board might measure slightly thicker than an uncoated one of the exact same GSM and fibre makeup.

Here's a quick look at how different finishes might affect perceived thickness:

-

Gloss Finish: Tends to be more compact, often feeling slightly thinner.

-

Matte/Uncoated Finish: Can have more air trapped, giving a bulkier, thicker impression.

-

Textured Finish: Often incorporates more air and fibre variation, leading to a noticeably thicker feel.

Practical Applications of Duplex Board Thickness

The thickness of duplex board, measured in microns, affects both appearance and durability. Thicker, higher GSM boards provide a premium feel and sturdiness, while lighter boards are easier to fold, mail, and handle.

Business Cards & Premium Stationery

For a professional feel, business cards and high-end stationery typically use 300–400 GSM duplex board (~0.30–0.45mm thick). A smooth, coated surface enhances color and text sharpness.

Packaging & Product Durability

Product boxes, especially with grey back board, need enough thickness to protect items during shipping. Thicknesses usually range from 0.35–0.50mm depending on weight and fragility, ensuring products arrive safely.

Brochures & Flyers

Marketing materials like brochures or flyers benefit from lighter boards (200–250 GSM, 0.20–0.28mm). They remain cost-effective, easy to fold, and simple to mail, while still maintaining decent print quality.

Here's a quick look at how thickness and weight often line up for common applications:

| Application | Typical GSM Range | Approximate Thickness (Microns) |

|---|---|---|

| Business Cards | 300-400 GSM | 300-450 µm |

| Premium Flyers/Brochures | 200-250 GSM | 200-280 µm |

| Product Packaging (Light) | 250-350 GSM | 250-380 µm |

| Product Packaging (Heavy) | 350-450+ GSM | 380-500+ µm |

Navigating Duplex Board Specifications

So, you've got a project and you're looking at duplex board. It can seem a bit confusing with all the numbers and terms, but it's really about matching the board to what you need it to do. Let's break down how to read those specs.

Interpreting Thickness Charts

When you look at a duplex board specification sheet, you'll often see a chart that lists different weights (GSM) and their corresponding thicknesses (microns or millimeters). It's not always a direct one-to-one relationship because how the paper is made, like how much it's compressed, can change its thickness even if the weight stays the same. For example, a 300 GSM board might be listed with a thickness range, say 0.35mm to 0.40mm. This variation is normal. You'll want to pick a thickness that feels right for your project something sturdy for a business card, maybe a bit lighter for a flyer.

Here's a quick look at how some common weights might stack up in thickness:

| GSM | Typical Thickness (mm) |

|---|---|

| 250 | 0.30 - 0.33 |

| 300 | 0.37 - 0.41 |

| 350 | 0.44 - 0.48 |

| 400 | 0.49 - 0.55 |

Note: These are general ranges and can vary by manufacturer.

GSM and Micron Equivalents

GSM (grams per square meter) indicates the board’s density, while microns (or millimeters) measure its thickness. They’re related but not identical a higher GSM usually means a thicker board, though processes like calendering can make it thinner while keeping the same weight. For reference, a 10pt board ≈ 0.254mm, which helps when comparing specs across suppliers or different paper types.

Choosing Based on Project Needs

Ultimately, the best duplex board for you depends on your specific project. Consider these points:

-

Durability: For items like business cards or product packaging, you'll want a board with a higher GSM and a suitable thickness for a premium feel and good resilience. A 300 GSM or higher is often a good starting point.

-

Print Quality: The surface finish and smoothness, often tied to the GSM and any coatings, will affect how well ink lays down. Smoother surfaces generally give sharper prints.

-

Foldability: If your project involves folding, like brochures or menus, a board that's too thick or stiff might crack. You might need to look at boards with a bit more flexibility, perhaps in the mid-range GSM.

-

Cost: While it's tempting to go for the cheapest option, remember that a slightly higher investment in quality board can lead to a better final product and fewer issues down the line. Finding that balance between cost and performance is key.

When selecting duplex board, always think about the end-use. A packaging box needs different properties than a greeting card. Checking the GSM and thickness together, and considering how the board will be handled and printed, will lead you to the right choice. Edicon Paper, a trusted duplex board manufacturer and supplier, offers a wide range of options including white back, grey back, and kraft boards in different GSMs, making it easy to find the perfect board for your project. Don’t be afraid to ask for samples if you’re unsure.

The Significance of Bulk in Duplex Paper

How Bulk Affects Feel and Performance

When you pick up a piece of duplex board, that initial impression of quality often comes down to its bulk. Bulk isn't just about how thick something looks; it's about how it feels in your hand and how it performs in different situations. Think about a business card versus a flyer. A business card needs to feel substantial, right? That heft, that density, is what bulk provides. It tells the recipient that this isn't some flimsy piece of paper.

For packaging, bulk can mean the difference between a product arriving safely or getting damaged in transit. A board with good bulk can resist crushing and tearing much better than a thinner, less dense option, even if they have the same GSM rating. It’s about that physical presence and the confidence it inspires.

Matching Bulk to Application Requirements

Choosing the right bulk depends on the board’s purpose. High-end brochures or folders need higher bulk for durability and a solid feel, while flyers or mailers can use lower bulk for easy folding and cost savings. It’s a balance of user experience, protection, and budget.

Here’s a quick look at how bulk can influence choices:

-

Premium Stationery (Business Cards, Letterheads): Higher bulk is preferred for a substantial, quality feel.

-

Product Packaging: Bulk is critical for durability and protection against damage during shipping and handling.

-

Brochures & Flyers: Moderate to lower bulk can be suitable, especially if ease of folding and mailing is a priority.

-

Point-of-Purchase Displays: Often requires higher bulk for rigidity and visual impact.

Wrapping It Up

So, we've looked at how GSM and microns relate to duplex board. Remember, GSM is about weight, while microns measure thickness. They often go hand-in-hand, but not always. Different paper types, like glossy versus uncoated, can have the same weight but different thicknesses. This matters for things like fitting your print into an envelope or just how sturdy it feels. Picking the right board means thinking about what you're printing and how you want it to look and last. It’s not just about picking the heaviest or thickest option; it’s about finding that sweet spot for your project’s needs.