Duplex Board vs SBS Board: Which One to Choose?

In choosing packaging materials to use in your business, the decision of which board to use between duplex board and sbs board can have a huge effect on the presentation of your product, costs and the overall success of visualizing a product. Both materials are useful in the packaging industry, but it is based on their unique attributes that will inform you on the right decision on your specific requirements.

These two types of paperboard are important in the packaging industry and have very specific advantages in different applications. Packaging food products, cosmetics or even pharmaceutical products? Then read this in-depth comparison to find out the key differences among these common packaging solutions.

What is a Duplex Board?

![]()

A duplex board is a multi-plied paperboard made up of two main layers which are bonded together in the process. On this packaging material, the top side is white which is suitable when printing and the bottom side can be of any color mostly grey or white depending on the nature of the application required.

The production process includes the mixing of recycled fibers with virgin pulp to produce a cost-efficient solution that is also durable as a packaging purpose. Optimally, the top layer is a bleached chemical wood pulp to print on, and the deeper layers are recycled or mechanical pulp.

Another variant of board coated duplex board having extra surface treatment to increase printable quality and aesthetics. These inexpensive versions are broadly accessible in the form of duplex board grey back or duplex board white back surfacing, tending to various packaging demands and financial status.

Understanding SBS Board (Solid Bleached Sulfate)

The top level of packaging materials is SBS board, also called solid bleached board or sbs paperboard. It is a high quality substrate that has been engineered completely out of bleached virgin wood pulp, giving a brilliant white finish through the entire thickness.

The sbs paper board manufacturing process consists of taking hard wood fibers by chemical pulping, bleaching the fibers so as to maintain a uniform whiteness producing a one or multi ply sheet. This forms a medium board with fantabulous printing abilities and superb surface smoothness.

The SBS paperboard is usually coated in clay mineral usually on either side of the paperboard and is able to print and have a more attractive look. The material is of high quality with superior printability, so it is the most advisable to go with in terms of high end packaging where the brand presentation is paramount.

Key Differences Between Duplex Board and SBS Board

![]()

Material Composition

Duplex board paper: It contains recycled fibers mixed with virgin pulp to come up with the cost-effective paper that still satisfies the moderate quality requirements. This combination saves manufacturing cost and offers satisfactory performance in most packaging needs.

SBS paperboard: This consists of 100 percent virgin bleached pulp and yields high quality at high costs of production. It is also evenly bleached and pure, and due to that it is appropriate as direct food contact for packaging purposes.

Cost Considerations

Duplex boards: come with substantial cost benefits compared to SBS alternatives. The use of recycled materials and use of easier manufacturing methods normally causes a 20-30% reduction of material cost when compared with high-end sbs board alternatives.

SBS paper board: This Board fetches high prices because it contains virgin fiber and needs intensive manufacturing conditions. But it is usually a worthwhile investment as it may lead to a better perception of the brand and high print quality on high-visibility uses.

Print Quality and Surface Properties

Coated duplex board: delivers good quality printing that can be used on most commercial prints. The white top side takes inks very well, but probably not as bright and crisp as higher-end options.

SBS board produces: It gives high-quality print with excellent ink absorption, reproduction of color and smooth finish. The even white surface allows two-sided printing and high-quality graphic uses.

What Applications Work Best for Each Board Type?

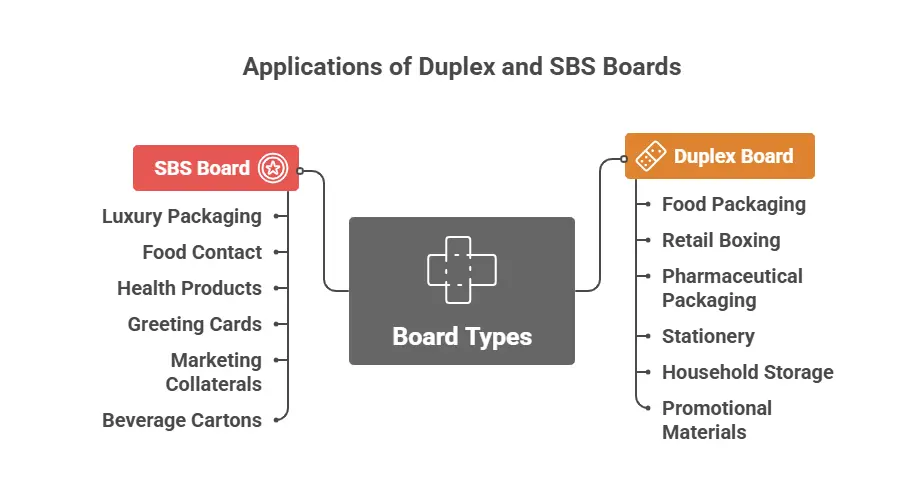

Duplex Board Applications

• Food Packaging and Trays: Duplex board has safe surface characteristics and strength and is commonly applied in bakery boxes, takeout trays, confectionary packaging and fast-food containers. Duplex board varieties that are coated are moisture resistant and suited to dry and semi-moist foods.

• Retail and consumer goods boxing: Duplex boards can be used in folding cartons, retail product boxes, toys, electronics and apparel packaging applications due to their blend of printability and rigidity.

• Pharmaceutical and Healthcare Packaging: Duplex board is often used on outer cartons of medicine, medical devices, and hygiene products, as they are as safe as appealingly branded.

• Stationery and Office Supplies: Products such as file covers, dividers and index cards can be made using duplex board paper because of its durability and thick customisable paper.

• Utility and household Storage: Household items, consumer organizers, storage boxes and shoe boxes are usually manufactured using duplex boards because of its strength and economy.

• Promotional and Display Materials: Duplex board is used to manufacture standees, point of sale displays and promotional folders due to high bulk and printable surface area.

SBS Board Applications

• Luxury Packaging: Suitable to high end cosmetics, perfumes, chocolate boxes and jewellery packaging where the packaging demands silky smooth whiteness and first class printing.

• Food Contact and Sensitive Goods: Direct packaging for dairies, bakery products, frozen foods and chocolates depends on the food safety, odorless, and the chemical purity of SBS board.

• Pharmaceuticals and Health Products: SBS board provides tamper-proof, hygienic, and aesthetically perfect packs of medicines, blister packs, and nutraceuticals.

• Greeting Cards and Stationery: The smooth glow surface and the brilliant white coat of the SBS board is preferred to the printing of greeting cards, wedding invitation, and high quality stationary.

• Premium Marketing Collaterals: SBS paperboard is used in presentation folders, gift packaging, and hard setting up boxes to get an upscale look.

• Premium Beverage Cartons: Wine, spirits and specialty beverages require this type of carton, because they need structural integrity as well as presentation of a luxury brand.

How Do Environmental Factors Influence Your Choice?

Sustainability Considerations

Duplex board: usually involves recycled material used by 80 - 100 percent, which makes it an eco-friendly solution to business sustainability. The less virgin fiber used means less environmental damage in the manufacturing process.

SBS board: manufacturing involves use of more virgin resources, but has great end-of-life recyclability. Sustainable forestry has become one of the most common ways in which the manufacturers reduce the effect on the environment.

What About Cost-Effectiveness and ROI?

Initial Investment Comparison

Duplex board suppliers: typically offer more competitive pricing, making this option attractive for high-volume applications where cost control is essential. The lower material cost enables businesses to maintain profitability while delivering adequate packaging performance.

SBS board: requires higher initial investment but can deliver superior ROI in premium applications where enhanced brand perception justifies the additional cost.

Long-term Value Considerations

Consider total cost of ownership, including potential damage reduction, brand enhancement, and customer satisfaction when evaluating options. SBS paperboard may offer better long-term value in applications where packaging quality directly impacts sales performance.

Duplex board white back provides balanced cost-performance for applications requiring good appearance without premium pricing.

Conclusion

The choice between duplex board and sbs board ultimately depends on your specific application requirements, budget constraints, and brand positioning strategy. Duplex boards offer excellent value for cost-conscious applications while maintaining adequate quality and performance standards. SBS paperboard provides premium quality and superior performance characteristics that justify its higher cost in applications where packaging quality directly impacts brand perception and consumer satisfaction.

Both materials serve important roles in the packaging industry, and understanding their unique characteristics enables you to make informed decisions that optimize both performance and profitability for your specific packaging needs. Consider your application requirements, budget parameters, and long-term brand strategy when making your final selection.

At Edicon Paper, we specialize in manufacturing and supplier premium-quality duplex paper board that meets the evolving needs of businesses worldwide. With a strong focus on quality, sustainability, and customer satisfaction, we ensure that our products not only enhance packaging but also add value to your brand.